The 100% Hungarian owned company was founded in 2020. It deals with condition survey and diagnosis of non-metal pipelines with modern, innovative robot technology.

What motivated us to build up our company? The fact that 40-60% of the pipeline network in Hungary was made from asbestos cement material, besides there are significant lengths of reinforced concrete (SENTAB) pipelines as well, mostly with large diameter. They have been operated for 40-50 years, that age means they are all above the originally planned lifetime.

The operation of these pipelines is not only non-economic, but at the same time they aren’t safe. There are often many failures that can cause serious damages and they are extremely dangerous because of their large diameter size. There are significant losses in the network therefore the safe and continuous service is not guaranteed.

Our goal is to make a diagnosis on these pipelines and provide useful information for the operating companies. Based on the results they can make the decision about the future of the diagnosed pipes.

-

What is the general condition of the pipeline?

-

Are there any damages inside: abruption or subsidence on the walls?

-

Are there any holes along the outside wall of the pipeline? (they can refer to leakage points or density issues on bedding

-

Does any corrosion appear in steel wires of concrete pipes?

-

Are there any visible density or joining issues that originate from mechanical damages?

After the diagnose we can define the future of the pipes:

- The pipeline still can be operated safe with a non significant expenditure for a while ·The operation of the pipeline is risky and insecure

- It can be repaired with Non-Dig procedure, and can be used (the physical solidity is enough)

- the complete change of the pipeline is needed

The completion of the exercises:

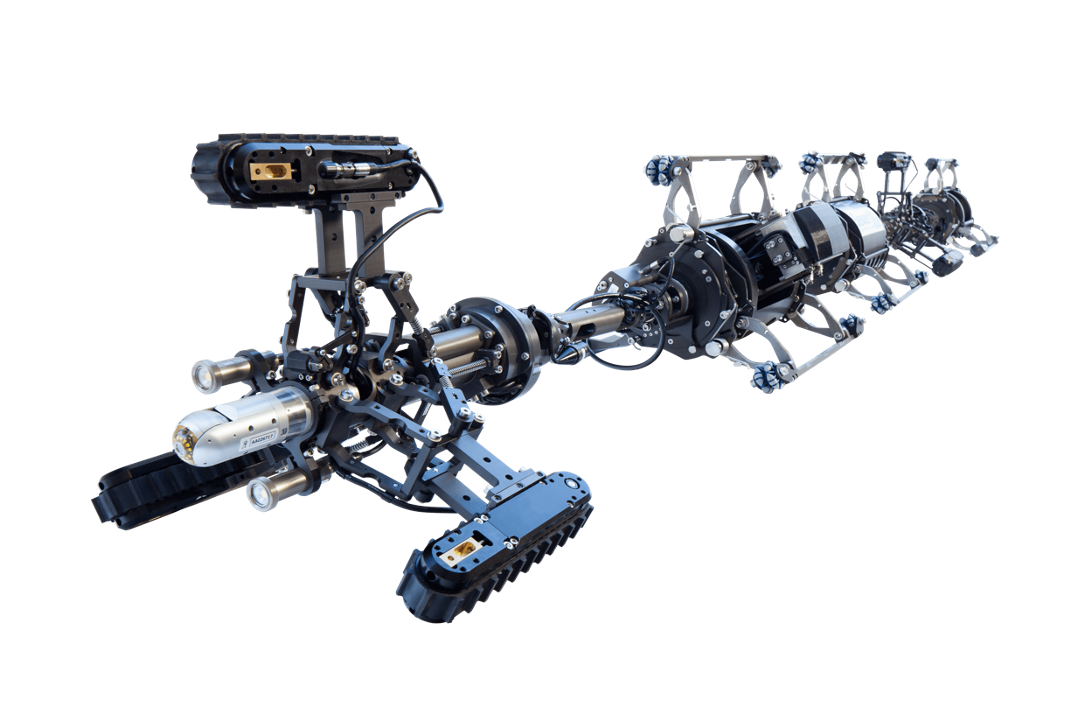

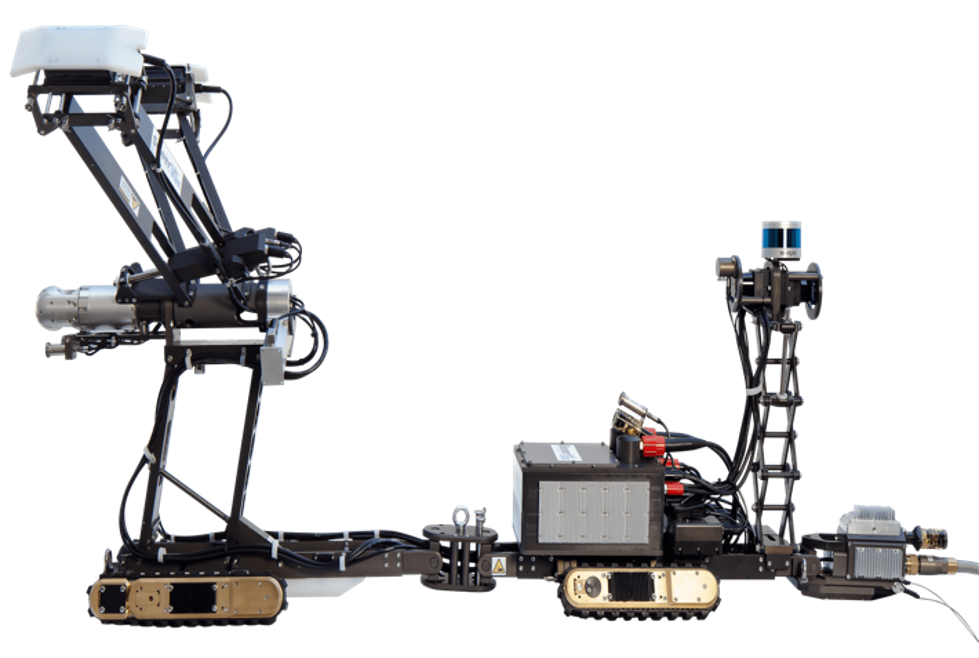

The applications were installed on two separate robots.

The smaller robot can be used for smaller pipes, it operates between the ACPS d250-500mm range and it is installed with CCTV and PPR systems.

The bigger robot called Surveyor can operate between the d525-1200mm range. Because of the size it is equipped with a LiDAR device beside the CCTV and PPR.

We can transport both robots in a special rebuilt vehicle (3,5 t) in the same place we can control. There’s a built-in crane in the vehicle as well. We can move the 150 kg of weight robots into the pit and back onto the vehicle, after they have finished. Besides, it has a complete IT station that controls the different units of the robot.

The control of the robots function through a 1000 m long cable drum that supports the power supply, the data transmission and helps in determination of distance. In case of any technical issues it helps to take out the robot from the pipeline.

The diagnosis are controlled by a technical engineer, who is supported by 3-5 technicians (number of personnel is depending on circumstances)

The criterion of accomplishing a diagnosis is that the pipeline has to be empty, the locks and the assembly have to be moved out from the pit in order to put the robots into the pipeline.

We make the report from the data that we earned during the process.

The report includes:

- Description in written form about the operation and the circumstances

- Diagrams about the wall and the holes of the pipeline with sizes

- Cross-section pictures based on determined distances with sizes

- Analysis in charts based on the recorded camera pictures by NASSCO PACP standards